ployether polyol moisture meter|polyether polyol material : tv shopping In this study, with the isosorbide as bio-based starting agent, a series of bio-based polyether polyols with different hydroxyl values were synthesized and used to prepare polyurethane . 23 de jan. de 2023 · 77M views 1 year ago Hit Videos. Madness ensues when a 'Player' in the world of romantic relationships finds a girl who's a worthy opponent. Tu Jhoothi Main Makkaar is a film .

{plog:ftitle_list}

Uma última como se chama quando a gente exagera para conseguir passar uma ideia. Por exemplo, quando a gente diz que chorou um rio de lagrimas ou repetiu a coisa mil .

In order to ensure consistency, the water content of the raw polyols must be monitored to maintain uniformity between raw materials. Because loss on drying is not possible as most polyols will evaporate at high temperatures, the .Moisture (%) [maximum] 0.04 Color (APHA) [maximum] 35 Appearance Free & Clear Viscosity @ 25 °C (cP) 1,000 Density @ 25 °C (lb / gal) 8.60 . CARPOL® PGP-4025 is a propylene glycol .The bio-based coatings prepared in this investigation provided useful physio-mechanical properties, chemical resistance, and water resistance compared to reference commercial .In this study, with the isosorbide as bio-based starting agent, a series of bio-based polyether polyols with different hydroxyl values were synthesized and used to prepare polyurethane .

Our expertise and library of 30,000 settings for different plastic resins ( e.g. PVC, PP, PE, PS,PET, PVC and many more) offer you an easy and reliable moisture analysis solution for all your plastic raw materials.The HX204 moisture analyzer can determine the moisture content of various plastics and resins, such as ABS (Acrylonitride butadiene styrene), PC (Polycarbonate) various types of PA .From pin-type to non-invasive moisture meters and hygrometers, Protimeter professional moisture meters and products make taking moisture readings a straight-forward process with dependable results.This application note provides a detailed method for the determination of water content in polyols using both volumetric and coulometric Karl Fischer (KF) titration. The method developed is in .

Moisture (%) [maximum] 0.02 Color (APHA) [maximum] 35 Appearance Free & Clear Viscosity @ 25 °C (cP) 75 Density @ 25 °C (lb / gal) 8.30 . CARPOL® PGP-400 is a propylene glycol .

Isocyanate-free moisture cure polyurethane coatings can be prepared using raw or functionalized soybean oil fol-lowing the generalized method shown in Figure 2. Similar polymers and coatings have been prepared and are com-mercially available using polyether polyols as the starting resin. 3 Polyol Preparation Typical polyols are polyether (such as PTMEG) or polyester (such as adipate esters). Properties are highly dependent on the nature of the polyol used. PU adhesives can be 1K moisture-curing reactive PU, PU dispersions, .Polyether polyols, which can be thought of as the backbone of many important polymers, are a group of polymers derived from simple alcohols and ethylene oxide or propylene oxide. They are the most widely utilized base in the production of polyurethanes, which are employed in a broad range of applications, including foam production, coatings .Metzger/McGuire Co. Polyether Polyol - 1 - 5/7/15 1. Identification 1.1 Product Name: Spal Pro RS-88 Part A Polyol 1.2 Recommended Use: Component of a Control Joint Polyurethane System Issue Date: 3/28/15 Supersedes: 6/20/13 Reason for revision: Update hazard statements 1.3 Manufacturer: Metzger/McGuire Co. PO BOX 2217

corning gorilla glass 3 hardness test

In particular, NX-9001 (formula PU 6) has replaced a sorbitol-based polyether polyol (PU 5), while NX-9008 and NX-9018 have been used as potential alternatives to a sucrose-based polyether polyol having a 360 mg KOH/g hydroxyl value.

Polyether Polyol CARPOL® MX-425 is a Mannich-based polyether polyol. The resulting product has a nominal functionality of approximately four and a targeted hydroxyl number of 425. The presence of amine in this polyol creates a material that is autocatalytic. Due to this, CARPOL® MX-425 is suitable for spray foam formulations in addition to .Before installing the radar level meter, engineers first carried out the design and parameter setting of the system. They selected a radar level meter suitable for polyether polyols and set the appropriate operating frequency and measurement range according to parameters such as the dielectric constant and liquid density of polyether polyols.summary of the MDI, TDI, and polyether production process. Figure 2. Process summary for the production of polyurethane building blocks. TDI by BASF is an 80:20 mixture of the 2,4- and 2,6-TDI isomers assaying 99.5% TDI minimum, as shown in Figure 3. TDI is produced in several grades that differ slightly in acidity and hydrolyzable chloride . Economic Impact Analysis (EIA) for the Proposed Polyether Polyols NESHAP. Polyether Polyols Production BID for Final Rule - Summary of Public Comments. Fact Sheets for Polyether Polyols Production NESHAP. View the supporting documents in the docket folder to find additional related documents to this rule. Compliance. Implementation Document for .

Moisture contaminated isocyanates may appear cloudy, may contain solid material at the bottom of the container, or . This is also a best practice for polyols. When working with meter mix equi pment it is best to have a low-pressure source of nitrogen providing a continuous nitrogen head to materials. Alternatively, meter mix equipment can be .

Recently, the preparation of PUFs with CO 2-based polyols has been attempted.An initial attempt to introduce PEC polyols into the formulation for flexible PU foams (FPUFs) was reported by Langanke et al. [].DeBolt et al. reported the preparation of FPUFs from blends of petroleum-based polyether polyols and CO 2-based PC polyols [].We also reported facile .Versatile polyether polyols give manufacturers more freedom. Which is why the Arcol® product line offers options for use across a wide array of products. This is possible because the range includes diol, triol and polymer polyols with molecular weights in that vary from less than 300 to as much as 6,000 g/mol.PPG polyether polyols are the most widely used and versatile group of polyols in polyurethanes, accounting for over 70% of the consumption in the market. . foam and CASE (Coatings, Adhesives, Sealants and Elastomers) markets. PPG polyols for CASE applications are lower in moisture values with higher end-hydroxyl functionality. Flexible Slab .

Abstract A novel UV/moisture dual-curable polyurethane resin has been synthesized via a two-step process. In the first step, methoxysilane-modified polyether polyol (SPOL) was prepared through the thiolene click reaction between sulfhydryl group in (3-mercaptopropyl)trimethoxysilane (KH590) and vinyl groups in polyether polyol. In the second . In comparison with the used polyether-type polyols, dimer fatty acid-based polyesters offer lower sensitivity to heat, oxygen and UV radiation, all of which attack ether bonds. The performance of dimer fatty acid-based .

>=1% Polyether Polyol CAS# is a trade secret 15 - 40% Alcohols, C12 - C15, ethoxylated propoxylated 68551-13-3 >=1% Polyether Polyol CAS# is a trade secret Massachusetts Right to Know Extraordinarily Hazardous Substance List: Concentration Components CAS-No. 1 - 5 ppm Acetaldehyde 75-07-0 1 - 5 ppm Furan 110-00-9their linear structure,polyether polyols are used to synthesize PU as thermoplastics,elastomers,and fibers (10).The overall advantage of polyether polyols lies in their high hydrophobicity,low cost,low viscosity,and increased flexibility.These factors made polyether polyols the market leader,and their popularity is still growing annually.

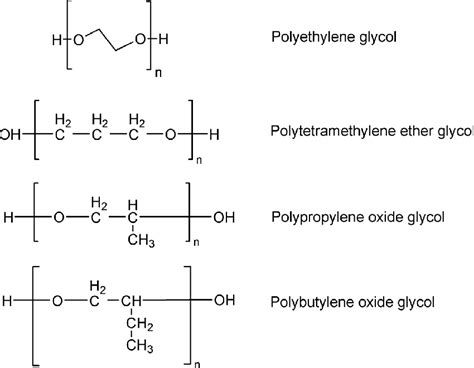

1 H-NMR spectra of polyether carbonate polyols before and after purification. Reaction condition: Catalyst amount = 50 mg, PO = 0.34 mol, PPG-600 = 0.25 mmol, toluene = 10 mL, PCO 2 = 30 bar, T P = 105 °C, t P = 3 h. As shown in Table 2, the DMC catalysts exhibited good to excellent activity for the PO/CO 2 copolymerization. Polyether polyols of this type are prepared by ring opening polymerization of alkylene oxides such as ethylene oxide (EO), propylene oxide (PO), and butylene oxide (BO) in the presence of a starter molecule such as water, glycerin, or a higher functionality initiator. Basic catalysts like potassium hydroxide have long been, and continue to be . Generally, polyether polyols with high functionality (3.0–8.0), low molecular weight (150–1000 g/mol), and high hydroxyl number (250–1000 mg KOH/g) are suitable for the production of rigid foams, . One-component systems consist of prepolymers with low isocyanate contents, which are cured by a reaction with moisture. Thus, .

The polyether polyol typically used has secondary (rather than primary) hydroxyl groups, to be less reactive than the primary alcohol polyols. The polyether backbone is generalized by the (- C – O – C - ) linkage. When reacted or extended with isocyanate, the resulting adhesive could be called a polyether urethane. The hydroxyl group-terminated polyurethane prepolymers were synthesized using polyether polyols, monools, and hexamethylene di-isocyanate. Polyurethane PSA sheets were obtained by adding the tri-functional isocyanate to the hydroxyl group-terminated polyurethane prepolymers, coating on nylon non-woven fabric, and curing for five days at 50˚C. Polyether polyols are a type of polyol used extensively in the production of polyurethanes, found in products ranging from flexible and rigid foams to coatings, adhesives, and elastomers. Unlike polyester polyols, which are produced through esterification reactions, polyether polyols are synthesized through the polymerization of epoxides (also .

Single-package systems — They are cured when exposed as a film to moisture, oxygen, or heat. Composition varieties: . Polyether polyols have low viscosity and high reactivity. This enables polyurethane coatings to become an alternative to 100% solid epoxy-based systems. These are used in coating applications for corrosion protection (DTM).The polycarbonate polyols are characterized by superior heat and moisture resistance vs. polyester polyols. Performance with Corresponding Urethane Elastomers . Polyether and polyester polyols also exhibit a variety of performance characteristics with specific regard to polyurethanes, such as hydrolytic stability, chemical resistance, and more.

Polyether polyols are made by the reaction of organic oxide and glycol. Main organic oxide utilized are. China is currently the largest producer of polyether polyol ,with production capacity is about 6 million tons, accounting for about half of the global total . Designed to meet the demand for high-performance, moisture-resistant coatings . Traditional polyurethane reactive hot-melt (RHM) adhesives make use of blends of polyester, polyether and, in rare cases, conventional petroleum-based polycarbonate polyols. Although polyesters and polyethers contribute properties to RHM adhesives such as good workability and rapidly building strength, polyesters have poor hydrolytic stability and .

corning gorilla glass 3 hardness test juryrigeverything

polyether polyols review

Ferramentas - InfoMoney - Informação que vale dinheiro

ployether polyol moisture meter|polyether polyol material